When to Replace Butcher Aprons for PPE Compliance

Share

- It’s Damaged: Tears, holes, or worn straps compromise safety.

- It’s Contaminated: Visible stains, odors, or food residue that won’t wash out.

- Water Resistance Fails: Liquids soak through instead of beading up.

- Transitioning Tasks: Switch aprons between raw and cooked food or allergens.

Quick Tips:

- Inspect aprons daily for damage or contamination.

- Replace aprons immediately after spills, tears, or exposure to high-risk materials.

- Use proper cleaning and storage methods to extend lifespan.

Staying compliant with OSHA and food safety regulations ensures worker safety and prevents cross-contamination. Regular checks and timely replacements are key.

When to Replace Your Apron

Wear and Tear from Daily Use

Daily butchering tasks can take a toll on aprons. Sharp tools, constant movement, and repetitive actions like bending, lifting, and reaching put pressure on straps and seams. Over time, this wear can weaken the apron, making it less effective at protecting workers and meeting PPE requirements.

Exposure to Food and Liquids

Handling meat, blood, and cleaning chemicals can gradually damage the apron’s material. To meet industry standards, aprons should be replaced immediately in these cases:

- Visible contamination during raw meat handling

- Permanent staining that can't be removed

- Loss of water resistance, reducing protection

These issues are directly tied to U.S. food safety rules, which prioritize hygiene and worker safety.

Safety Guidelines and Compliance

U.S. workplace safety laws require proper care and maintenance of PPE, including aprons. Food safety regulations specify when aprons must be replaced to ensure cleanliness and prevent cross-contamination:

| Situation | Required Action |

|---|---|

| Between shifts in high-traffic areas | Use a fresh apron |

| After handling different allergens | Replace immediately |

| Switching from raw to cooked food | Wear a clean apron |

| Following major spills | Change apron right away |

| If fabric is torn or damaged | Remove from use |

The Food Standards Agency has highlighted that poor cleaning practices are a leading cause of food business violations . A "clean as you go" approach, where spills and contamination are addressed immediately, helps maintain hygiene and reduces cross-contamination risks throughout the day.

For aprons with chainmail components, extra care is needed. Any holes or missing links must be addressed immediately to ensure they meet safety requirements.

Appropriate Ways to Wear PPE in Food Production Areas

4 Warning Signs to Replace Your Apron

Here are four clear signs that your apron might no longer meet safety standards.

Physical Damage

Damage to your apron can reduce its ability to protect you. Regularly check for these issues:

- Cracks or tears in the material

- Pinholes larger than 2 mm

- Deep creases or lines that worsen over time

- Shifting or bunching of protective layers

If the damage is in areas that shield vital organs, replacement is critical. Always follow safety guidelines or the manufacturer's advice when assessing damage .

Stubborn Stains

Permanent stains do more than ruin the look of your apron - they can signal compromised hygiene and fabric integrity. Tonya Harris suggests, "Washing it as soon as possible can prevent stains and odors from setting in" . Consider replacing your apron if you observe:

- Stains that don't come out after proper washing

- Food residue that persists despite cleaning

- Odors that linger, hinting at trapped contaminants

- Changes in texture around stained spots

Loss of Water Resistance

Water resistance is key to keeping spills from soaking through. To test your apron, splash a little water on it. If the water doesn’t bead up and instead absorbs into the fabric, the protective coating may have worn off.

Damaged Straps and Closures

Faulty straps or closures can compromise your apron’s safety. Look out for:

- Torn or frayed straps

- Loose or broken buckles

- Velcro that no longer sticks

- Worn or damaged edges

If these fastening systems are no longer secure, it’s time to replace your apron .

sbb-itb-c693c43

How to Make Aprons Last Longer

Taking care of your aprons not only helps them last longer but also keeps them safe and effective for use.

Cleaning Steps

Keeping your aprons clean is a key part of making them last.

Cotton and Synthetic Aprons

- Wash cotton aprons in warm water (90–105°F) and synthetic ones in cold water using a gentle cycle with mild detergent.

- Add a splash of vinegar during the rinse cycle.

- Use mesh laundry bags to keep straps from tangling.

- Dry on low heat or let them air dry to avoid damaging the fabric.

Special Materials

- Leather: Use lukewarm water and natural soap for cleaning. Avoid treating specific spots to prevent uneven wear.

- Waxed Canvas: Spot clean with a damp cloth - no need for full washing.

- Garment-Dyed Fabrics: Wash separately in cold water and line dry to maintain color and texture.

Safety Checks

"PPE equipment must be checked regularly by competent staff and in accordance with the manufacturer's instructions. Regular testing and maintenance reveal instances where the manufacturer's recommendation is to replace the PPE. Evidence of wear and tear such as tears in clothing, broken fasteners, loose seams, and heavy soiling are all indicators that it is time to replace your PPE."

To keep your aprons safe and functional, follow these steps:

- Check straps and fasteners for damage before every use.

- Look for signs of wear like tears, loose seams, or heavy stains during routine inspections.

- Keep a record of all inspections.

- Train your team on proper care and maintenance practices.

These steps ensure your personal protective equipment (PPE) stays in good condition.

Storage Methods

Proper storage is the final step in protecting your aprons after cleaning and inspections:

| Apron Type | Storage Method | Extra Tips |

|---|---|---|

| Leather | Hang on hooks | Condition monthly |

| PVC | Store in a cool, dry place | Keep out of direct sunlight |

| Cotton/Synthetic | Hang on hooks or hangers | Avoid folding |

Buying New Aprons

After making the most of your current aprons, here's what to keep in mind when choosing a compliant replacement.

Materials and Protection

Different tasks require different levels of protection. Here's a quick breakdown of popular materials:

| Material Type | Level of Protection | Best For | Drawbacks |

|---|---|---|---|

| PVC Coated | High resistance to water and chemicals | Heavy meat processing | Not very breathable |

| Heavy-duty Rubber | Excellent liquid protection | High-moisture environments | Can feel warm during long shifts |

| Vinyl | Good water resistance | Standard butchery tasks | Prone to cracking in cold storage |

| Polyethylene | Lightweight and protective | Light processing tasks | Less durable than other options |

Required Safety Standards

Choosing a butcher apron that meets PPE requirements means paying attention to specific safety standards. Here's what to look for:

Essential Features:

- Use materials that resist moisture and prevent liquid penetration.

- Opt for tear-resistant fabrics for durability.

- Adjustable straps are a must for a secure and comfortable fit.

- Surfaces should be easy to clean to help reduce bacterial growth.

Compliance Checklist:

- Perform a hazard assessment to identify the level of protection needed.

- Ensure materials comply with food safety regulations.

- Balance protection with ease of movement for efficient work.

Once you've checked these boxes, explore options from trusted brands like Cosmic Aprons.

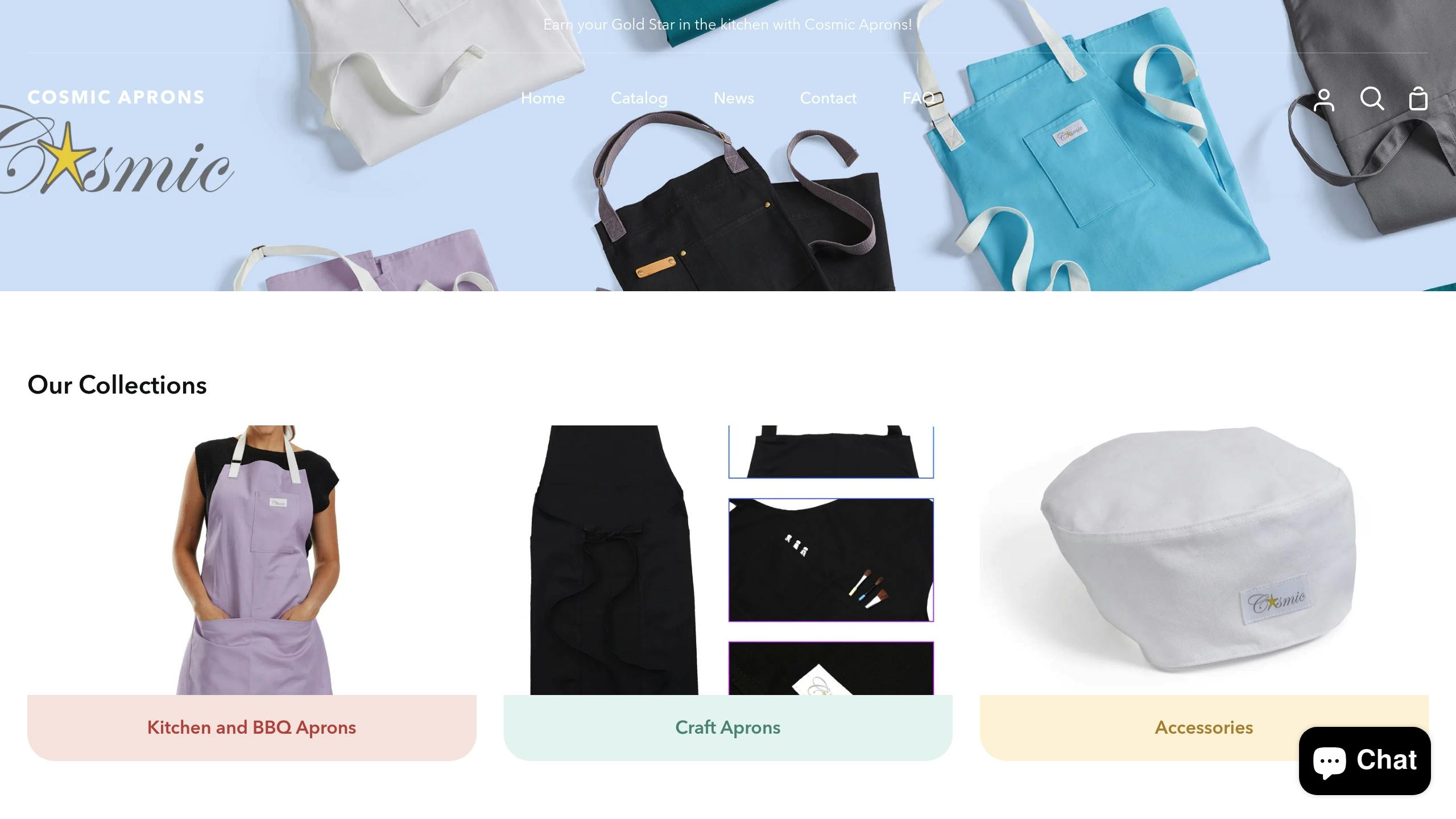

Cosmic Aprons: Professional Kitchen Aprons

Cosmic Aprons offers durable, adjustable aprons designed for professional kitchens. Their products feature heavy-duty construction, practical pockets, and easy-to-clean materials.

"Adjustable chef aprons epitomize the perfect blend of comfort, resilience, and functionality."

When it comes to protective coatings, here are some options to consider:

| Coating Type | Level of Protection | Durability |

|---|---|---|

| PU Coating | High water resistance | Good |

| Fluoropolymer | Maximum waterproofing | Excellent |

| Silicone Elastomer | Strong stain resistance | Very Good |

Summary

Keeping a close eye on PPE and replacing it when necessary is key to staying compliant with OSHA regulations. Employers are required to provide PPE, like aprons for food safety, at no cost to employees . Here's what you need to know:

When to Replace Aprons:

- Replace contaminated aprons immediately.

- Switch out aprons daily between shifts to maintain hygiene .

- Discard aprons showing visible damage or wear.

- Change aprons when transitioning between high-risk food handling tasks .

Practical Cost Management:

- Always have spare aprons available for emergencies .

- Use regular laundering schedules to extend apron usability .

These steps help control costs while maintaining a safe work environment.

Why It Matters:

- Properly maintained aprons protect workers from cuts and injuries .

- Following safety standards reduces the risk of foodborne illnesses, safeguarding both employees and customers.

A strong PPE program fosters a safer workplace. Make sure your aprons meet current safety standards and review your PPE practices regularly to ensure maximum protection.